Equipment Features

Electric system:Electric safety circuit protection, CE certification

Control system:Multi-axis servo motion controller, full servo motor control

HMI:LCD Color touch screen display interface

Unwinding device:Independent automatic tension control system

Auto splicing:Nonwovens and packing film non-stop auto splicing with spliced joint automatic rejection system. Two sets of label applicator which can be operated by auto switch mode or synchronous mode

Wipes cutting module:Rotary cutting roller

Cleaning and disinfection :Hygiene grade design, easy to disassemble conveyor belts which contact with liquid are designed accord with hygiene standard

Wetting flow control:Electronic flowmeter control wetting flow, reduce recycle liquid, wetting range 2.5-4.5 times

Liquid level control :Electric liquid level sensor control liquid level automatically

Pipeline disinfection:Pipeline and pump use lowest point drain out design and 3D design standard, no residue and free of dead corner, apply to pasteurization or CIP (Clean In Place)

Spectral decomposition detection:Nowoven, label, packing film, wetting weight, packaging on-line monitoring

End seal protection function:To prevent the end seal device cut onto wet wipes

Automatic web guider (optional devices):Automatic web guiders for jumbo roll to ensure high speed stable running and folding accuracy

Quality control (optional devices):Nonwoven stain detection, Metal detection, Checkweigher, Date code & Die cutting & Labelling visual inspection, and automatic sorting reject

SCADA application program (optional devices):(Supervisory Control And Data Acquisition) equipment operating and detection data output port

Applied nonwoven material :Spunlace or flushable materials and else nonwovens

Nonwoven specification:Maximum W1050mm, Φ1200mm, coreφ76.2mm(3”), online slitting

Nonwoven quantity:8 rolls of nonwoven, non-stop auto splicing, 4 rolls running and 4 rolls standby

Applied packing film:PET/PE, BOPP/PE, PET/AL/PE laminated film and other heat-seal materials

Packing film specification:Maximum W420mm, Φ360mm, coreφ76.2mm(3”)

Packing film quantity:2 rolls of packing film, non-stop auto splicing

Applied sticking label:Transparent sticker & non-transparent sticker

Sticking label specification:Maximum W100mm, Φ400mm, coreφ76.2mm(3”), 2 rolls of lable, non-stop switch

Fold type:Not pop up extraction or Pop up extraction

Folded size:L130-200mm, W95-115mm (otherwise indicated)

Unfolded size:L130-200mm, W180-210mm (otherwise indicated)

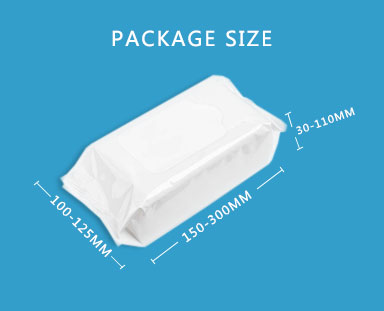

Package size:L150-300mm, W100-125mm, H30-100mm (otherwise indicated)

Production speed:80 ppm or 400 cpm or 8000 wipes/min, whichever comes first

External dimension:L20900mm, W4590mm, H2350mm

Rated power:AC380V (Customizable), 50/60Hz, three-phase five-wire, 33KW

Compressed air:0.6-0.8Mpa, 130L/min

Net weight:About 20000KGS

Other optional devices:Automatic web guider, Nonwoven stain detection system, Metal detector & Checkweigher & Reject, Date code printer, Package visual inspection and reject, SCADA system

ZHENGZHOU ZLINK MACHINERY AND EQUIPMENT CO.,LTD

ADD:6 BUILDING, BOAO TECHNOPARK, JIAN SHE NAN ROAD, ZHONGMU, ZHENGZHOU, HENAN, CHINA,

POSTCODE: 451450

TEL:0086-371-60192168 0086-37160192968

FAX:0086-371-60198608

E-MAIL:export@zlinkmc.com

WEB:http://www.zlinkmc.com

JAPAN BRANCH

ADD: 〒134-0083,東京都江戸川区中葛西4-9-20,

グランフィールド葛西502

TEL: 090-8284-8577

EMAIL: shigeru.r@zlinkmc.com

KOREA BRANCH

ADD: #101-211, PYEONGTAEK-RO 17, PYEONGTAEK-SI, GYEONGGI-DO, KOREA, POST 17917

TEL: 0082-31-654-8838

MOB: 0082-10-31646432

EMAIL:peterpark@zlinkmc.com

INDIA BRANCH

ADD: 43-A, KAUSALIYAPARK SOCIETY, NEAR MAHENDRA BROTHERS DIAMOND FACTORY, JAMALPOR, NAVSARI - 396445, GUJARAT, INDIA

TEL: 0091 99040 45331

EMAIL: piyush@zlinkmc.com, sales.india@zlinkmc.com